How much can you earn by automating the finishing process?

Find out with Trebi RVS

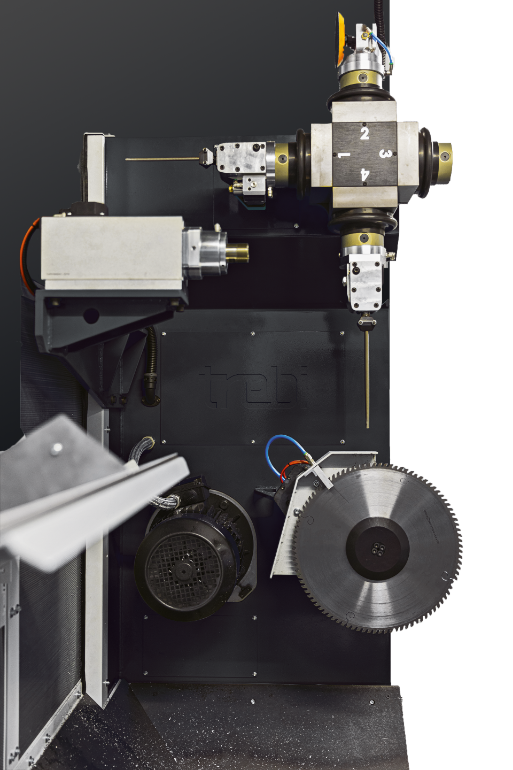

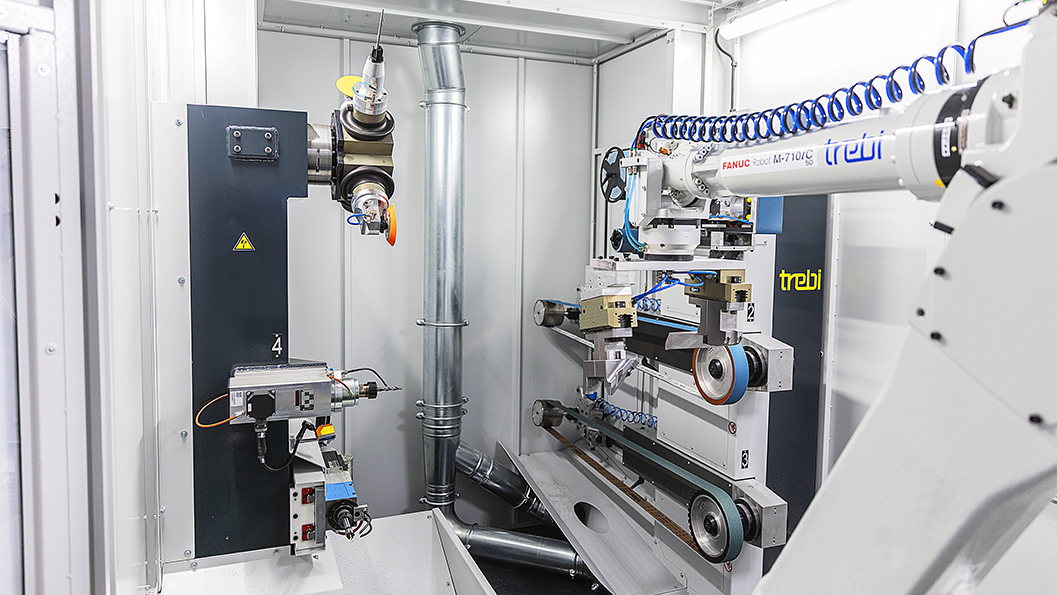

The first system that allows you to verify the economic advantages deriving from the automation of the deburring process in your foundry even before building the robotic system.